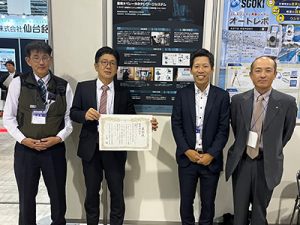

The practical verification of construction machinery remote operation utilizing "K-DIVE®" at the landslide disaster countermeasures construction site won the prize at the awards, organized by the Japan Construction Machinery Construction Association.

※K-DIVE®:Solutions for Construction Site Improvement with “Remote operation system” and “Operational date”

Our three models of wired electric hydraulic excavators obtained the initial certification as GX Construction Machinery from the Ministry of Land, Infrastructure, Transport and Tourism.

The practical verification of construction machinery remote operation utilizing "K-DIVE®" at the landslide disaster countermeasures construction site won the prize at the awards, organized by the Ministry of Land, Infrastructure, Transport and Tourism Kinki Regional Development Bureau.

※K-DIVE®:Solutions for Construction Site Improvement with “Remote operation system” and “Operational date”

Our crawler crane "Mastertech7200G NEO" won the prize at the 53th Innovative & Inventive Design Excellence Award IDEA organized by The Nikkan Kogyo Shimbun (Japanese newspaper company).

SK1300DLC won Innovation Award at the World Demolition Summit 2022 held in Vienna, Austria on November 16 and 17 of 2022.

Innovation Award, which we submitted for this time, is judged on "innovation", and the judging panel of professionals evaluated the characteristics of SK1300DLC: assembly, disassembly, and transporting, as well as the distinctive parking position of the four-piece machine.

World Demolition Summit 2022 Official Website’s Awards Page

In June 2021, Kobelco Construction Machinery received Kurumin Certification as a company supporting child-raising from Minister of Health, Labour and Welfare.

A "child-rearing support company" is stipulated in the Act on Promotion of Measures to Support Raising Next-Generation Children, which was enacted in 2005 to respond to the rapid declining birthrate. Companies formulate an action plan for improving the employment environment to balance work and child-rearing and the Minister of Health, Labor and Welfare approves companies that have achieved their goals and met certain standards.

We have been certified for the introduction of flexible work styles such as telework, efforts to reduce overtime hours through work style reform activities, and measures to promote the use of a balancing support system such as childcare leave.

Our 7 ton class new model SK75SR-7, which greatly improved the functionality and comfort, received “the 50th Innovative & Inventive Design Excellence Award IDEA” sponsored by The Nikkan Kogyo Shimbun (Japanese newspaper company).

※This award is given to products with excellent functional beauty and efficiency out of machinery field and a judging committee composed of external experts selects the award-winning products.

In April 2019, seven Japanese companies, including Kobelco Construction Machinery, jointly opened SriCity Japanese Companies JIM, aiming for human resource development in the manufacturing sector in India, and it was accredited as Japan-India Institute for Manufacturing (JIM) by the Japanese Ministry of Economy, Trade and Industry.

JIM is a part of an initiative of Manufacturing Skill Transfer Promotion Program agreed between the governments of India and Japan in 2016.

Kobelco Construction Machinery U.S.A.INC. was selected as one of the organizations (including individuals) which propelled Spartanburg County into the future at the 100th anniversary ceremony of the Spartanburg Area Chamber of Commerce. The growth, success and great future of the Spartanburg Plant was recognized and it won “Economic Futures Award” this time.

Kobelco Construction Machinery began implementing the Kobelco "carbon offset program", an original program based on the Japan Carbon Offsetting Scheme, in October 2013 to further contribute towards global warming prevention and forest maintenance. This substantial undertaking has been highly evaluated, earning Tohoku Area Assistance Award for the "Third Tohoku Area Carbon Offset Award" supported by Tohoku Bureau of Economy, Trade and Industry.

Kobelco Construction machinery group exhibited 14 works at “Karakuri Kaizen Exhibition 2017” sponsored by Japan Institute of Plant Maintenance, and our work got a gold prize at the hand truck contest. Including this year, we have been participating this exhibition for 9 years running.

Kobelco Construction machinery group exhibited 10 works at “Karakuri Kaizen Exhibition 2016” sponsored by Japan Institute of Plant Maintenance, and “Kuru-kuru COOL kun (work name)” got a gold prize at the hand truck contest, which was a special project in the exhibition.

Kobelco Construction Machinery began implementing the Kobelco "carbon offset program", an original program based on the Japan Carbon Offsetting Scheme, in October 2013 to further contribute towards global warming prevention and forest maintenance. This substantial undertaking has been highly evaluated, earning the Minister of Agriculture, Forestry and Fisheries Award for the "Fifth Carbon Offset Award" supported by the Ministry of the Environment, the Ministry of Economy, Trade and Industry, and the Ministry of Agriculture, Forestry and Fisheries. This was the first time that a construction machinery manufacturer was recognized for the award by each minister.

The "MK650" lattice boom wheel crane for harbor use (maximum lifting capacity of 65 tonnes) received "Good Design Award 2015" sponsored by the Japan Institute of Design Promotion.

For harbor cargo handling which calls for efficiency in a short period of time, maximizing the lifting capacity for this class and the substantial improvement in mobility served as factors for the high evaluation.

With the approval of the Hiroshima Institute of Invention and Innovation's promotion of science education projects, Kobelco Construction Machinery has been conducting a home delivery science class as part of the company's CSR activities since 2010. This continuing effort was highly evaluated. Currently, the home delivery science class is teaching elementary schoolchildren the principle of balance and levers using a miniature hydraulic excavators.

Following the establishment in June 2013 of Kobelco Construction Machinery Europe B.V., Kobelco Construction Machinery's overseas subsidiary, the company was recognized for its continuing active investments in business expansion, employment growth and other endeavors. This resulted in the company receiving the Netherlands Foreign Investment Agency (NFIA) and the Dutch & Japanese Trade Federation (Dujat) sponsored "Deshima Netherlands Award 2013" in the "new investment" category.

Kobelco Construction Machinery announced the world's first hybrid excavator monitor machine in the spring of 2006, and launched it as the "SK80H" hybrid excavator in 2009.<br>

Earning recognition for this advanced effort, the "SK80H" became the first hybrid excavator to receive "The Minister of the Environment's 2010 Commendation for Global Warming Prevention Activity (technology development and commercialization category)".<br>

In 2012, following "SK80H", we developed and commenced sales of "SK200H", a 20-ton hybrid excavator model.

As the first building demolition machine to receive the award, the "SK135SRDLC" demolition machine with common use type main boom received the "Good Design Award 2009" sponsored by the Japan Institute of Design Promotion.<br>

With easy mounting and dismounting of the boom or arm at the end of the main boom, the unit was recognized as an operating machine capable of handling a variety of on-site tasks.

The 7-ton model ACERA GEOSPEC hydraulic excavators "SK70SR/SK75SR+/SK75UR" and the 13-ton model hydraulic excavators "SK125SR/SK135SR/SK135SRLC/SK130SR+" received the "Good Design Award 2008" sponsored by the Japan Institute of Design Promotion.<br>

Recognized for their outstanding contributions to the environment and safety, the units are excellent in terms of their low fuel consumption and low noise.

Japan

The Rough-Terrain Crane "PantherX 250" received the "Good Design Award 2008" sponsored by the Japan Institute of Design Promotion. The unit was highly regarded for its design which allows it to "blend into a city backdrop without an intimidating presence".

The community beautification activities of the employees of Kobelco Construction Machinery earned the recognition of Tokyo's Shinagawa district where the company's headquarters is located. These activities included cleaning out the withered flowers from the flower beds in front of the headquarters building, picking up trash and using rainwater from the Meguro River for sprinkling. Also, member companies of the Kobelco Construction Machinery Group throughout Japan were involved in activities such as cleaning up surrounding flower beds and picking up trash.

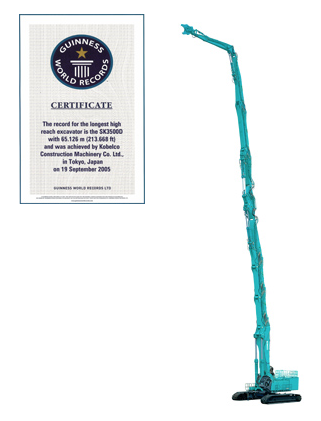

The "SK3500D" demolition machine for extra-large buildings, featuring the world's maximum working height of over 63 meters, was recognized as "the world's tallest building demolition machine" by Guinness World Records. The machine is capable of disassembling a 21-story building at ground level.