MADE BY KOBELCO (Universal Quality)

K-SWaT Activity

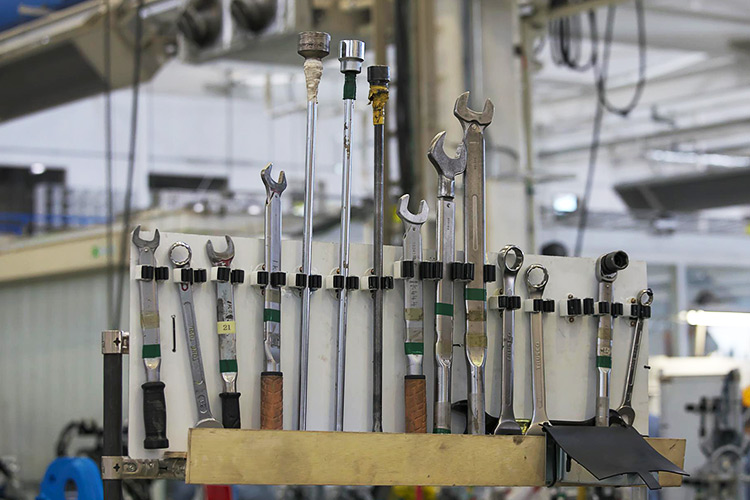

K-SWaT (KOBELCO Standardized Work and Time) activities were undertaken to define the standard work

in KOBELCO’s production process by reviewing and improving the defined standard work.

For the future, these activities focus on structuring a production line that isn’t dependent on operators.

In addition, they aim at achieving even higher levels of quality

for the development of new machines while taking production into full consideration.

Aiming at New Heights

The Challenge of Work Standardization

Up until now, production consisted of rough work procedures and the order of installation depended on operator's levels of knowledge and skill. As a result, working hours and work allotment varied on each occasion.

To resolve this issue, we began our K-SWaT activities which defined the standard work as the installation order of parts at a very detailed level of action. To develop work standardization, the division of labor must be adjusted according to the production of various machines as well as to the changes in cycle time. The more detailed the standards are, the higher the hurdle becomes. Added to this, the difference in the facilities and layout of each factory requires a standardization for each of them.

To clear these obstacles and pursue an even higher level of quality, we promoted the activities from our Itsukaichi Factory, one of our "mother factories". There, we train our operators who will spread our activities to their respective production bases in order to standardize our work at all production bases.

KOBELCO production takes into consideration everything

from development to manufacturing

In addition to production lines that don’t depend on operators, K-SWaT activities have another merit. That merit is to be able to adapt the production viewpoint at the new product development stage. With the work standardized in the production process, the production lead time can be calculated and it makes possible to develop high quality and safety products by considering production efficiency.