Technology

A Prosperous Recycling Society

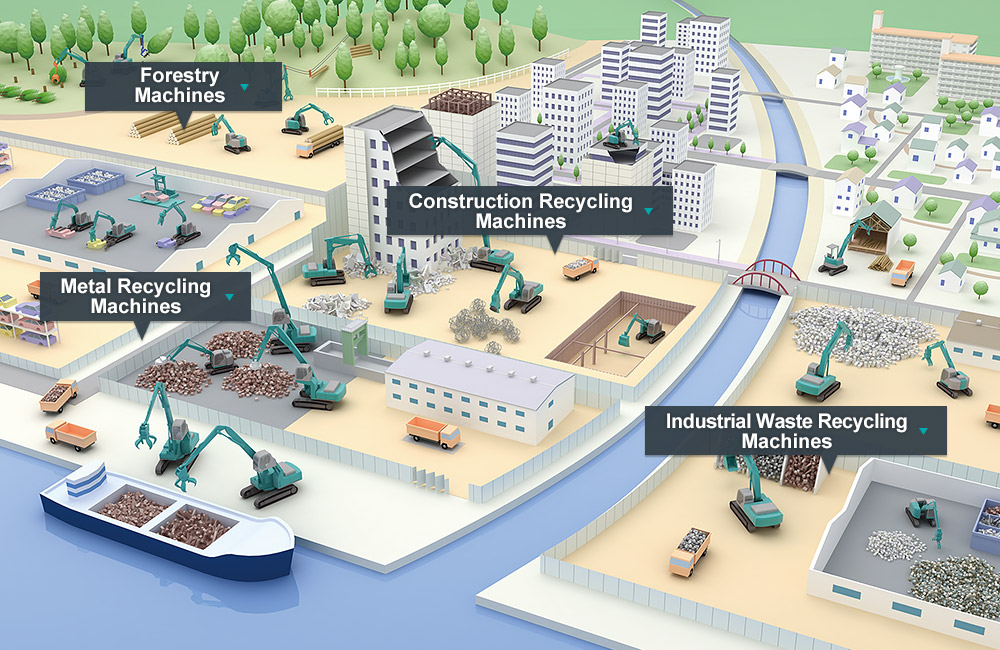

KOBELCO's Environmental Recycling Machines

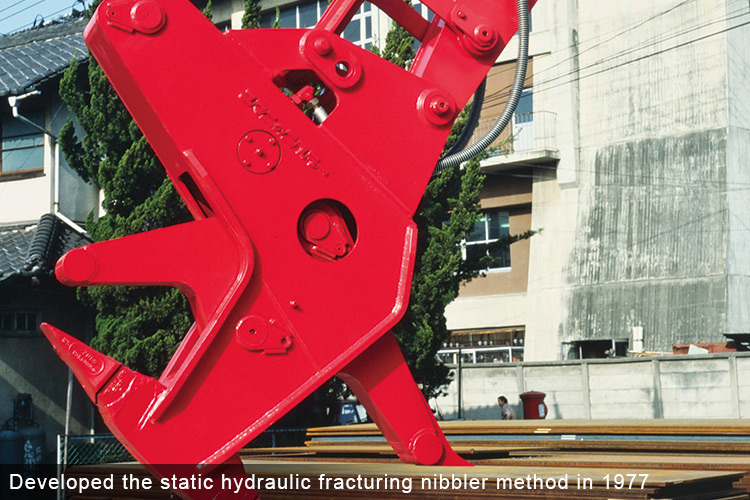

In the latter half of the 1970s, as society underwent a change from consumption to recycling,

KOBELCO began focusing its efforts on an environment for the next generation.

KOBELCO has progressed to develop machines specializing in various applications

such as for forestry, metal, and industrial waste recycling, and kept producing clean and environment-friendly products.

Industrial Waste Recycling Machines

Expand the Possibilities of Business

Social environmental concerns and the enforcement of various recycling laws have resulted in an annual improvement of the recycling rates for industrial waste including wastepaper, metal waste, rubble and waste materials. We KOBELCO focus on expanding the potential of the industrial waste recycling business by developing machines aimed at improving efficiency for handling operations such as loading/unloading of waste from vehicles and throwing the waste to processing machines at each stage. We support the expansion of the industrial waste recycling business by offering recycling machines that can contribute from various angles including throughput expansion and stable operation as well as labor savings, safety maintenance and cost reduction which can lead to increase profits.