Environmental Preservation Measures

Reducing Industrial Waste

As a part of our efforts to reduce waste at the Itsukaichi Factory of the Hiroshima Factory, we are switching from the use of cardboard for the packaging material of parts delivered by our suppliers to the use of specialized plastic pallets in order to reduce the amount of waste cardboard. These actions have been highly praised, leading to Hiroshima City presenting this factory, where we are actively introducing measures to reduce the amount of waste and increase recycling, on the city's official website as an example of efforts to reduce industrial waste by large-scale producers of such waste.

Reducing the Amount of Waste of Substances Harmful to the Ecosystem (Class I Designated Chemical Substances under the PRTR system)

Some painting material required for painting products contain substances that could be harmful to the health of humans or the ecosystem (Class I Designated Chemical Substances under the PRTR system). At our Okubo Factory, we have changed the paint materials used for painting to ones that are not harmful to humans or the ecosystem, which has resulted in a reduction of the amount of harmful materials among the waste disposed by the factory. We will continue to implement such environmentally friendly measures at all of our production bases.

Implementing "Green Procurement Guidelines"

Green procurement refers to measures implemented by the Japanese Ministry of the Environment to give priority in procurement from companies that are pro-actively providing products and services with a low environmental impact, and implementing measures to protect the environment. KOBELCO CONSTRUCTION MACHINERY has created our own internal Green Procurement Guidelines and we have signed agreements regarding these guidelines with all 210 of our suppliers to which they are applicable.

We are continuously striving to reduce the environmental burden not only within the KOBELCO CONSTRUCTION MACHINERY GROUP but also through such cooperative efforts together with our suppliers.

Safety and Environmental Measures in Production Processes

* Example showing production processes at Itsukaichi Factory

White Paint for Indoors

Walls and floors are painted white, and the factory is designed to allow for the use of natural light to provide brightness

No Uneven Surfaces Inside Factory

No uneven surfaces improves worker safety

Assembly Line-type Painting Processes

Installation of assembly lines for shot blasting, under and over coats, and drying improves efficiency

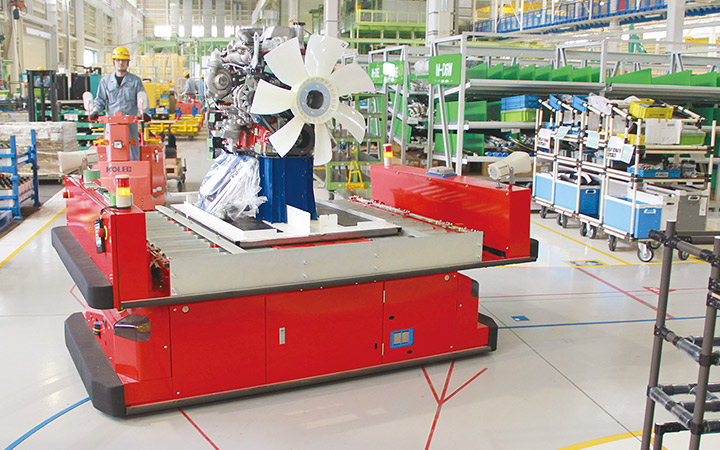

Automated Guided Vehicles (AGV)

Improved transport safety and optimized work efficiency

Clean Meters to Monitor Dust Levels

Constantly monitor dust levels to prevent dust and other particles from entering

Shipping from Itsukaichi Port

Many overseas-bound shipments are loaded at the nearby Itsukaichi Port to ship them across the globe

Environmental Figures

Emission Amounts Associated with Business Activities

The KOBELCO CONSTRUCTION MACHINERY GROUP is carrying out various environmental conservation activities according to the business cycle of development, production, distribution and sales. Our efforts for environmental preservation include measures at each factory to reduce CO2 emission such as those to reduce energy use and waste matter, as well as production and development-related activities that focus on creating products with low fuel consumption and other improved environmental performance.

The FY2018 environmental figures for our Japanese production bases are shown below.